The salt industry at Grand Saline began even before Texas gained its independence from Mexico in 1836. The first salt produced here was manufactured by the Cherokee Indians, who seeing the ground covered with a white frosting of saline matter and that the water in the small lakes was brackish, called the area Saline Prairie.

From the water, the Indians manufactured salt by boiling salty water in iron kettles until the water was all evaporated, leaving the salt behind. Then they carried the salt to Nacogdoches and sold it to merchants.

Tradition has it that Indians came for miles in every direction to Grand Saline for salt, used sometimes to remedy rheumatism. This trade soon attracted industrialists and land speculators and they began to search for the salt lands where the Indians were bringing the product from.

A man named Jordan discovered the Saline Prairie and marked a trail to it. Then in 1845 he and Allen T. McGee acquired title to the land and called the place Jordan Saline.

With two iron wash pots brought from Nacogdoches as equipment, they began to manufacture salt. They added more pots and increased their output as demand increased. They continued this until 1849 when McGee was appointed postmaster.

According to the History of Van Zandt County, written by W. S. Mills, the earliest most worthy and progressive citizens reached the county by the 1850s. Among these were the Jordans, Kuykendalls, Horsley, McGee and others.

By act of the legislature on March 20, 1848, Van Zandt County was created out of territory of Henderson County, and by the same act Jordan's Saline was designated as the county's capitol for two years.

When Wood and Rains Counties were cut off from Van Zandt in 1850 and made separate counties, fixing Van Zandt's boundaries as at present, it came necessary to locate a new county seat nearer to the geographical center of the county.

In December, 1857 Hamm bought out Jordan and McGee's interest and continued salt manufacturing by iron kettles.

The output of salt then was small because of poor transportation facilities and crude manufacturing.

In 1859 Samuel Richardson, a Kentucky native, bought out the salt manufacturing industry conducted by Frederick Hamm and began to manufacture salt. On the southern portion of the prairie he erected his furnace on an elevation at the foothill. He put down a well on the prairie above the head water lake and put in a mule-powered pump.

In 1872 the Texas and Pacific Railroad was extended from Marshall to Dallas, passing through Jordan's Saline. A depot was erected and the name of the settlement was changed to Grand Saline.

When the Civil War came, the salt works was taken over by the Confederate government, and returned to Richardson after the war was over, in 1867.

Without a doubt (Margaret Hall states in her book History of Van Zandt County,) salt was the major wartime county industry. But who directed operations those four years is unclear.

To convey the brine from the well to the furnace or kettles Richardson built a pipe by boring sweet gum logs from 10 to 16 feet and pinned them together to make a continuous tube.

After moving to Dallas, where he laid out Richardson addition, he returned to Grand Saline to put down the first deep well, piercing the rock salt bed several hundred feet. He put in a salt plant on the Texas and Pacific Railroad, which he operated until his death in 1900.

In the latter eighties, a Major Byron Parsons of South Bend, Ind., came to town with the idea of putting in a modern salt mine, hoping to turn out salt for table and dairy purposes. But Richardson had a monopoly of the salt land and wouldn't sell to anyone.

Richardson wanted a depot for Grand Saline, so he deeded 50 acres of land, where the town now lies, to Gen. Granville M. Dodge of Iowa.

Dodge laid out the land in blocks and lots as they appear today. A few lots west of Main Street running north from the depot had been sold, but most of that part of the town still belonged to the Texas and Pacific Railroad, and was wild wood.

Parsons contracted with the Texas and Pacific for its holdings in the western half of the original town of Grand Saline on the condition he could find salt there.

Parsons took a small room in the old depot while he put in a test well, and in deep tangled wild wood, he discovered solid rock salt.

His salt plant contained a barrel factory and dairy salt plant, and was called Lone Star Salt Company. Later Parsons severed his relationship with the company and it then was bought by Morton Salt.

By 1929 Morton Salt had opened a salt mine 1-1/2 miles south of a small town called Kleer Mine. For years two iron kettles used to boil down brine from the marsh in early days, were placed along Hwy 80 at town boundaries. One has since disappeared. The other sits in front of Westward Ho Motel to this day. One was said to be one of the two Jordan brought to Grand Saline in 1849.

A year later Richardson also installed steam lines in his pans, and salt production increased to about 600 barrels a day. This increased salt production, bought (sic) about increased population, and on December 16, 1895, Grand Saline became incorporated.

Grand Saline recorded a number of firsts shortly before incorporation.

The first school in Van Zandt County was taught by James H. Kuykendall in winter 1849-50, five miles south of Grand Saline.

In 1873, Richardson opened the first general store in Grand Saline. The first school building was erected about 1890 where the city hall now stands. The first Methodist Church was on O'Hara Street with Rev. Large pastor, while the first newspaper was printed in 1893 by J. B. Spinks, with H. B. Baird as printer's devil.

The first brick buildings here were erected by T. B. Meeks in 1890 and by J. E. Persons.

A. Wilderspin was first mayor, T. B. Beeks (sic), Dr. Kuykendall, Lou Sparks, George Scott, John Yarbrough and T. M. Joslin were first councilmen. L Jones was chosen its first city marshall.

By 1901 the Fielder Salt Company organized south of the Lone Star Company followed by the Southern Salt Company in 1903.

Then in 1904, B. W. Carrington and Company bought Fielder Salt Company holdings.

During this time, the Richardson plant passed through several changes of management and ownership before Richardson's death in 1900.

The Grand Saline Salt Company was organized in 1904, from Richardson holdings, but the company was short lived. In 1917 the plant was destroyed by fire. It was rebuilt and put in operation again only to be destroyed by fire once more in 1919.

The plant never was rebuilt and the holdings of the company were sold to Morton Salt Company in 1920.

In the meantime, B. W. Carrington and Company continued to operate the Fielder and Lone Star plants until 1913. But in 1920, Morton Salt took over holdings of B. W. Carrington and Company. It has operated the plant ever since.

In 1929 Morton Salt decided to open a mine in the salt dome to meet the demand for grades of rock salt. After prospecting, a shaft was started about 1-1/4 miles south of Grand Saline.

The surface plant was completed and the mine put in operation January 28, 1931.

By 1929 Morton Salt prepared to mine rock salt from extensive underground deposits. Early in 1929 it bought a 140-acre tract one mile south of town.

That same year oil was discovered in Van and afterwards independent entrepreneurs and five New York companies, which later consolidated, secured land between Grand Saline and the Sabine River but both failed to strike oil.

But Grand Saline did prosper as a result of the oil discovery. By October 24, 1929, 12 petroleum supply companies, five lumber yards and several warehouses opened, and G. W. Greene opened an "electric shop."

To meet demands for improved transportation, the Texas and Pacific Railroad increased shipments from 12 to 40 cars, Delta Airways scheduled regular stops on a graded runway and Red Line taxis carried passengers to Van.

Western Union opened an office in M & M Hotel and Southwestern Telephone rebuilt local lines. A White way - street lighting - was installed in business and residential areas.

During the Depression the county received federal aid to help alleviate hard times, and in 1935 because road improvements were needed a $45,000 WPA grant graveled and asphalted streets in Grand Saline. Persons from around the county were employed to build sewers in town and in 1937 sewing rooms opened in Grand Saline.

In 1948, the era of salt plants in town died when the B. W. Carrington plant burned to the ground. It was located where Brookshires Grocery now stands.

Morton Salt then moved its evaporating plant adjacent to the rock salt plant. This plant was completed and operating by May, 1950 and by 1953, Van Zandt County was noted as the greatest salt producer in Texas.

The history of Grand Saline and its chief industry, salt is as fascinating as the discovery of gold - at least to the city's occupants.

Just imagine, if you will......

A primitive Cherokee Indian rode through the wild, untamed region of the reservation in an area just beginning to be called Tejas. Sunlight filtered through the heavy shade of trees and brush overhead. Getting thirsty, the brave stopped at a yet unexplored pond in the newly acquired reservation and fell to the ground at the water's edge for a drink, He took one long swallow before his nose wrinkled and he spat the water out. He smelled of the water then and took a smaller, more cautious drink. The pond water had a strange, yet familiar tang. A smile broke out on his face as he remembered the taste. Once a trader had exchanged a tiny bag of granules of the same flavor with him for hides. Why, it had to be salt!

Leaping back on the horse, the brave rode back into camp to share the discovery with his friends. Within days they had rigged equipment to hold the water for solar powered evaporation. In a few weeks they had salt, crude and coarse, but still salt. And so the industry began in what was later to become Grand Saline.

A decade later, the reservation was pushed further west and the land opened for settlement. In 1845 John Jordan and A. T. McGee signed a partnership contract for producing the salt the Indians had discovered. The few scattered cabins and the salt works had to have a name so it was called Jordan's Saline.

The wto men improved upon the original production by devising a boiling method to extract salt from the brine. Large black iron kettles were strung over a fire, the water boiled away and the salt was packed in bags.

Frederick J. Hamm leased the Jordan and McGee salt works in Jordan's Saline in 1850 and later bought their interests in 1857. Ownership of the salt works passed hands again in 1859 when S. Q. Richardson purchased the Hamm holdings. Richardson modernized the production methods by digging shallow wells (brine had previously been taken from the salt marshes) and installing a pump operated by oxen and treadmill. A primitive pipe line constructed from hollowed gum logs transported the brine from the wells to the kettles. Even with all Richardson's improvements, though, salt was still transported by wagon to other towns.

The Confederate Government confiscated the salt works during the Civil War and operated the plant at a 100 sack per day production rate.

Richardson's salt works was returned to him after the war. He gradually increased production to 250 sacks per day. Then in 1872 the Texas and Pacific Railroad was extended from Marshall to Dallas via Jordan's Saline speeding the transporting process. A depot was constructed and the town was renamed Grand Saline. The township was located at the present site, adjacent to the salt works and the railroad.

Management of the plant changed hands again in 1875 when Richardson leased the company to a St. Louis company managed locally by G. M. Overlease. This company modernized the plant to the extent that the old iron kettles were replaced with large shallow pans and the sun's heat was used for evaporation rather than fire (reverting to the original Indian method).

Richardson again took management of the plant after a few years and about the same time the salt dome was reached for the first time by a well. The brine from this well had a much higher density of salt then surface water and therefore was more desirable.

The Richardson plant was soon to face its first competitor. Major Byron Parsons organized the Lone Star Salt Company in 1891 right across the railroad tracks from the Richardson plant. He brought in a new procedure installing steam lines, which increased production tremendously.

Soon after, Richardson too, installed steam pipe lines under his evaporating pans.

The two companies were producing so much salt that the town's population increased and the city was incorporated on December 16, 1895.

Fielder Salt Company, another competitor, was organized in 1901 and was followed by the addition of Southern Salt Company in 1903. The additional plants doubled Grand Saline's daily salt production level.

From 1904 through 1906 B. W. Carrington and Company purchased Fielder Salt, Lone Star Salt & Southern Salt companies. S. Q. Richardson died in 1900 and 1904 the heirs of his estate sold to Grand Saline Salt Company organized by Emerson Carey and J. Kirk.

Several events contributed to Morton Salt's purchase of the total Grand Saline salt production. First T. S. McGrain bought an interest in the Grand Saline Salt Company in 1905 and came to town as manager. He increased the production level and operated it at a 750 barrel per day capacity until the plant burned in 1917. The plant was rebuilt, only to succumb to fire again in 1919. That plant was not rebuilt again. McGrain sold his holdings to Morton Salt in 1920. Morton's also bought the B. W. Carrington and Company plant in 1920 which was producing an amazing 2,000 barrels per day at that time.

The old Carrington plant was destroyed by fire in 1948, but Morton's had already opened a mine directly into the salt dome in 1929. A vacuum pan evaporation plant was built at the mine site. After the Carrington plant burned Morton Salt Company built a new evaporating plant adjacent to the mine which was completed in 1950.

Now, 58 years later, Morton Salt Company still owns complete interest in the salt deposits of Grand Saline. This is one of only three mines owned by Morton's in the entire world. Salt is produced locally in every form from coarse rock salt to Nature's Seasonings and fine grained iodized table salt. They even make salt blocks for cattle. Salt has come a long way since those Cherokee Indians first discovered its existence in Van Zandt county. Today salt is used not only for cooking and seasoning, but for aspirin, automobiles, bar soap, ball point pens, writing paper, cotton shirts, wool sweaters, leather shoes and synthetic apparel. In fact there are an estimated 14,000 uses for salt in industry.

Salt is possibly one of the main reasons that Grand Saline has stayed on the map and not just drifted away, the fate of too many pioneer settlements. Grand Saline may be a small town but many people nationwide know it as the town that put salt in their shakers.

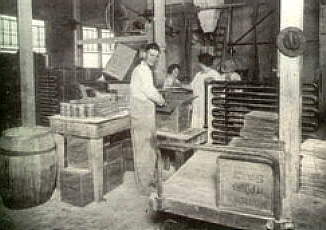

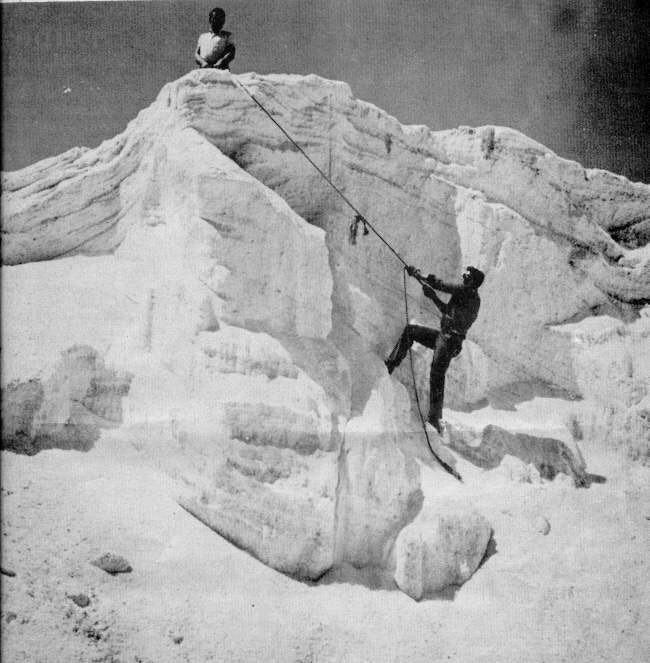

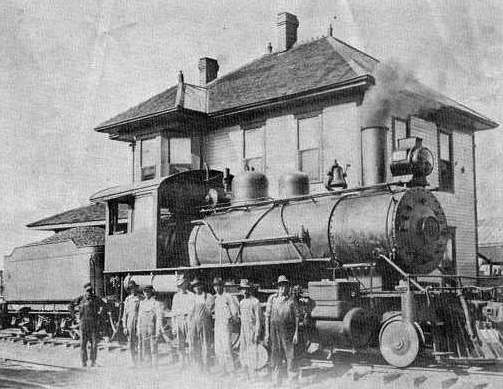

Photographs of interest pertaining to this page. The photos on this page were furnished by David Monk (deceased) and the Van Zandt County Historical Commission reprinted with their permission from The Pictorial History of Van Zandt County 1848-1994.

Old Salt Works a view of one of the earlier salt works on the Salt Flats southeast of Grand Saline. Taken from the 1980 edition of The Grand Saline Sun donated by David Monk (deceased).

Salt Mountain a huge "mountain" of salt created by Morton Salt to help employees hone their mountain climbing skills. Taken from the 1980 edition of The Grand Saline Sun donated by David Monk (deceased).

Shortline Railroad in 1917 played a vital part in the growth of Grand Saline's Salt Industry. Coal was transported from Alba to Grand Saline. Three of the men pictured are identified as Wood Macie, Duke White and Dick Taborn. Photo taken from the 1978 edition of The Grand Saline Sun donated by David Monk (deceased).